A Innova

Trabalhamos para fazer o futuro nos produtos estirênicos, resinas e transformados plásticos.

Na área petroquímica, fabricamos o etilbenzeno (EB) e, a partir dessa substância, obtemos o monômero de estireno (SM), produto central da economia e precursor da própria resina que fabricamos, o poliestireno em suas variações.

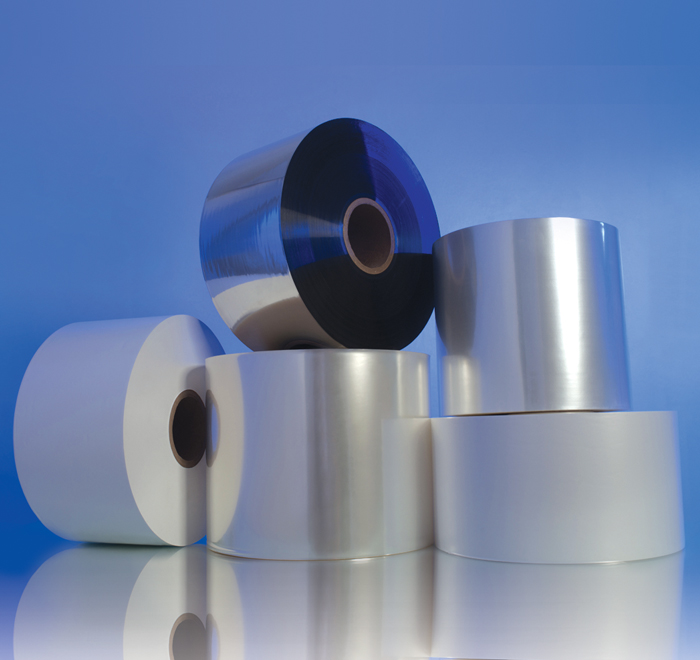

Na área de transformação plástica, fabricamos filmes de polipropileno biorientado (BOPP), laminados plásticos em bobinas de poliestireno e polipropileno e tampas plásticas para garrafas PET de água mineral, sucos e refrigerantes.

Onde tudo começou

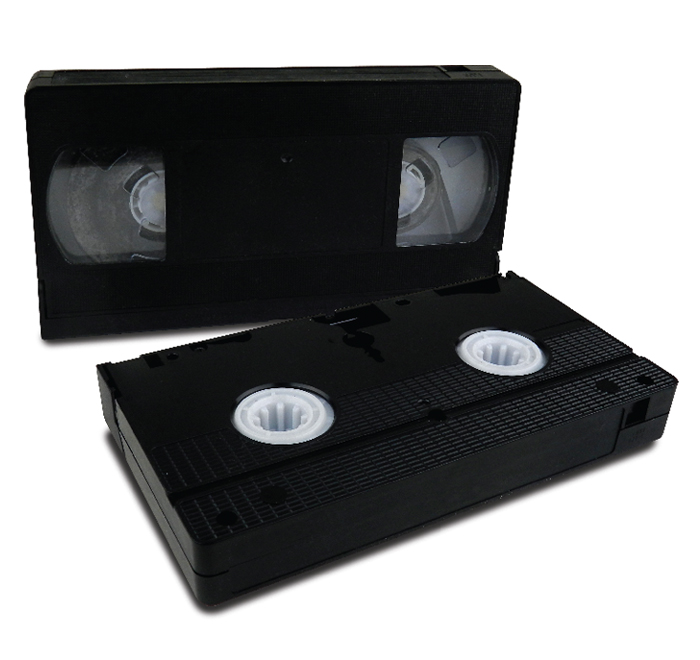

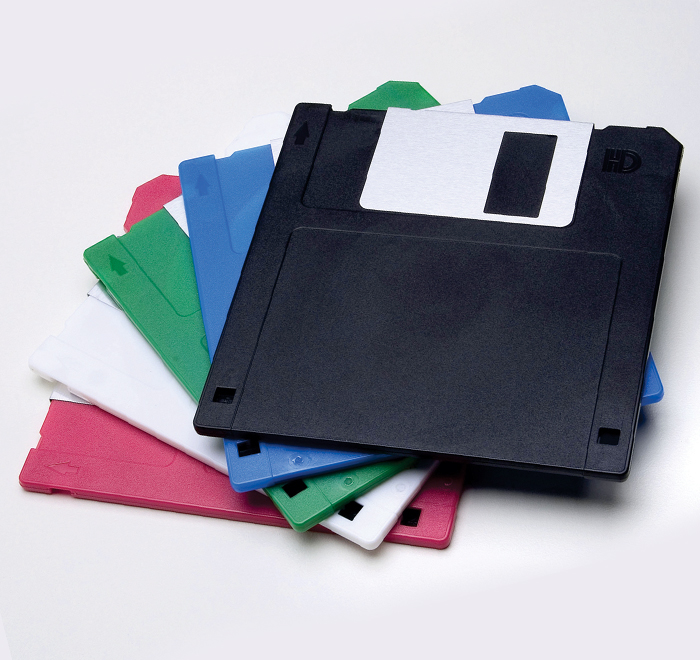

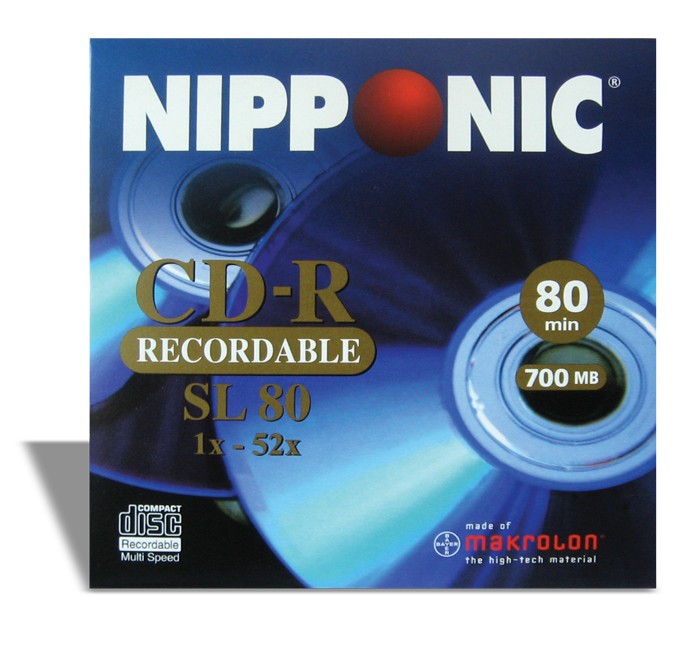

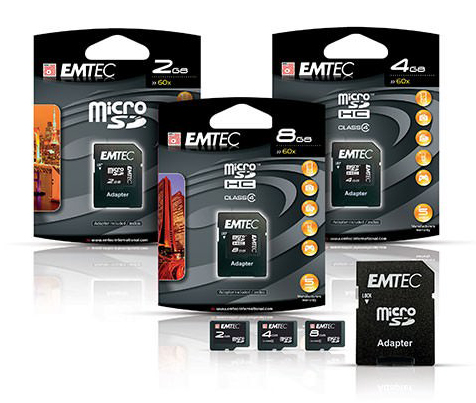

A Innova tem como origem a Videolar, indústria fabricante de suportes de mídias virgens e pré-gravadas: fitas magnéticas de vídeo VHS, áudio cassetes, disquetes, pen drives, CDs, DVDs e discos Blu-Ray. Fundada em 1988, na cidade de Caixas do Sul (RS), a Videolar se consolidou como maior fabricante de mídias do país com uma produção verticalizada e consagrada como única no mundo, atendendo de ponta a ponta a praticamente todo o mercado: fabricação, faturamento e entrega simultânea para todo o Brasil a partir de Manaus. Os grandes estúdios de Hollywood representados no Brasil (chamados majors) e as distribuidoras independentes tornaram-se livres dos estoques e da operação logística para exercer foco em marketing e vendas.

No curso da sua história, a Companhia deu um passo estratégico em 2002: transformou-se de maior consumidora nacional de poliestireno em fabricante da resina: ao construir a primeira petroquímica da Região Norte, passou a suprir o consumo próprio, destinado aos estojos das mídias e fitas VHS, bem como tornou a resina disponível às diversas fábricas do Polo Industrial de Manaus, como as dos segmentos de gabinetes para eletroeletrônicos, materiais escolares e de higiene. Assim, foram lançadas as bases para o ingresso e o crescimento nos negócios petroquímicos que se ampliaram em seguida à indústria da transformação plástica, com a fabricação dos filmes de polipropileno biorientado (BOPP) e tampas para garrafas de água mineral, sucos e refrigerantes.

Linha do tempo

Missão

Liderar em nossos negócios, oferecendo confiança e laços fortes aos clientes e colaboradores, postura sustentável ao meio ambiente e retorno aos acionistas.

Visão

Saber ouvir, desenvolver e entregar: há sempre uma necessidade clara.

Uma Companhia líder apresenta soluções.

Valores

Conduta comprometida e ilibada;

Capacidade de adaptação;

Foco total nas demandas do cliente.

Nossas Unidades

ESCRITÓRIO CENTRAL, ALPHAVILLE, BARUERI (SP)

ESCRITÓRIO CENTRAL, ALPHAVILLE, BARUERI (SP)

Área construída: 27.032 m²;

Área total: 29.999 m²

Av. Tamboré, 25 – Alphaville

06460-000 Barueri SP

Tel.: +55 (11) 4197-7000

- Comercial e Administração

UNIDADE I, MANAUS (AM)

UNIDADE I, MANAUS (AM)

Área construída: 64.000 m2;

Área total: 289.314 m2

Av. Torquato Tapajós, 5555 – Tarumã

69041-025 Manaus AM

Tel.: +55 (92) 3878-9000

- Filmes plásticos de polipropileno biorientado (BOPP)

- Laminados plásticos em bobinas de poliestireno (PS) e polipropileno (PP)

- Tampas plásticas para garrafas PET de águas minerais, sucos e refrigerantes

UNIDADE II, TRIUNFO (RS)

UNIDADE II, TRIUNFO (RS)

Área construída: 174.929 m²;

Área total: 242.000 m²

BR 386, Km 419, Pólo Petroquímico do Sul

95853-000 Triunfo RS

Tel.: +55 (51) 3457-5800

- Etilbenzeno (EB)

- Monômero de Estireno (SM)

- Poliestireno de Uso Geral (GPPS)

- Poliestireno Alto Impacto (HIPS)

- Poliestireno Expansível (EPS)

- PS-3D

- Central de Geração de Vapor e Energia Elétrica (CGVE)

- Centro de Tecnologia em Estirênicos (CTE)

UNIDADE IV, MANAUS (AM)

UNIDADE IV, MANAUS (AM)

Área construída: 26.904 m²;

Área total: 67.048 m²

Av. Abiurana, 1616 – Distrito Industrial

69075-010 Manaus AM

Tel.: +55 (92) 2101-7800

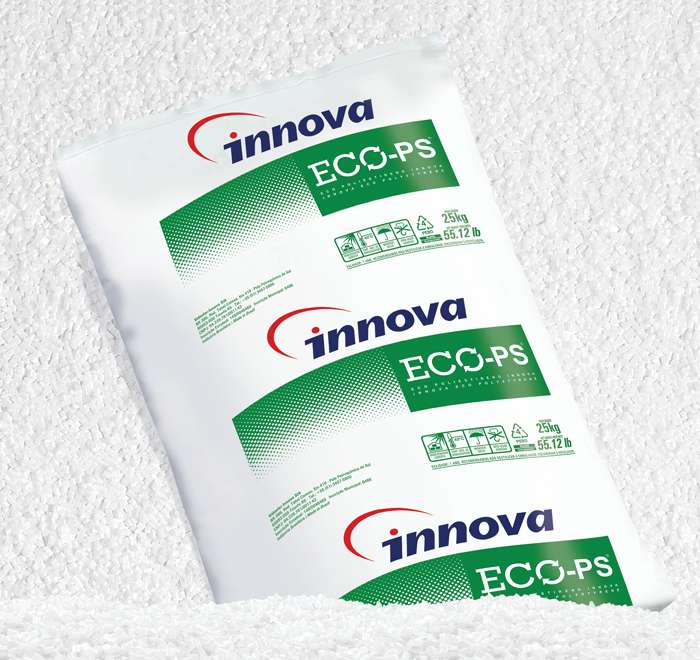

- Poliestireno de Uso Geral (GPPS)

- Poliestireno Alto Impacto (HIPS)

- ECO-PS®